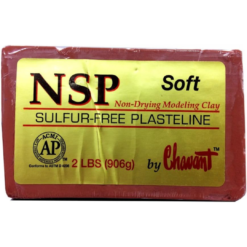

Unique Properties

NSP can be softened with heat to be troweled, brushed, or liquified for casting into silicone molds.

Physical Properties

Durometer:

Soft: 24A

Medium: 33A

Hard 51A

NSP Soft and Medium Density: 99 lbs./cu. ft. Specific Gravity: 1.58 g/cc

NSP Hard Density: 99 lbs./cu. ft. Specific Gravity: 1.58 g/cc

Softening Temperature

NSP Soft = 120°F / 49°C

NSP Medium = 125°F / 52°C

NSP Hard = 130°F / 54°C

Troweling Temperature

175°F / 80°C

Brushing Temperature

185°F / 85°C

Casting Temperature

205°F / 97°C

Max Temperature

205°F / 97°C

Hygiene

Wash hands with soap and water after use.

Handling Tips

NSP™ clay scrapers and rake tools are often used to initially make the clay surface uniform. NSPTM is very solvent friendly; solvents such as naphtha, clear mineral spirits and turpentine are aggressive solvents which can be used to quickly soften and dissolve the surface. Citrus based solvents such as D-limonene can also be used but may cause inhibition when molding the clay using silicone rubber. 99% Isopropyl alcohol can be used to smooth the clay surface if a less aggressive solvent effect is desired.

NOTE: If isopropyl myristate is used on the surface of NSP™, the surface will remain soft, and it will not return to the original hardness.